Weather Stop

Provides

Effective Insulation

Solutions to

Southern IN

&

Northern KY

Provides

Effective Insulation

Solutions to

Southern IN

&

Northern KY

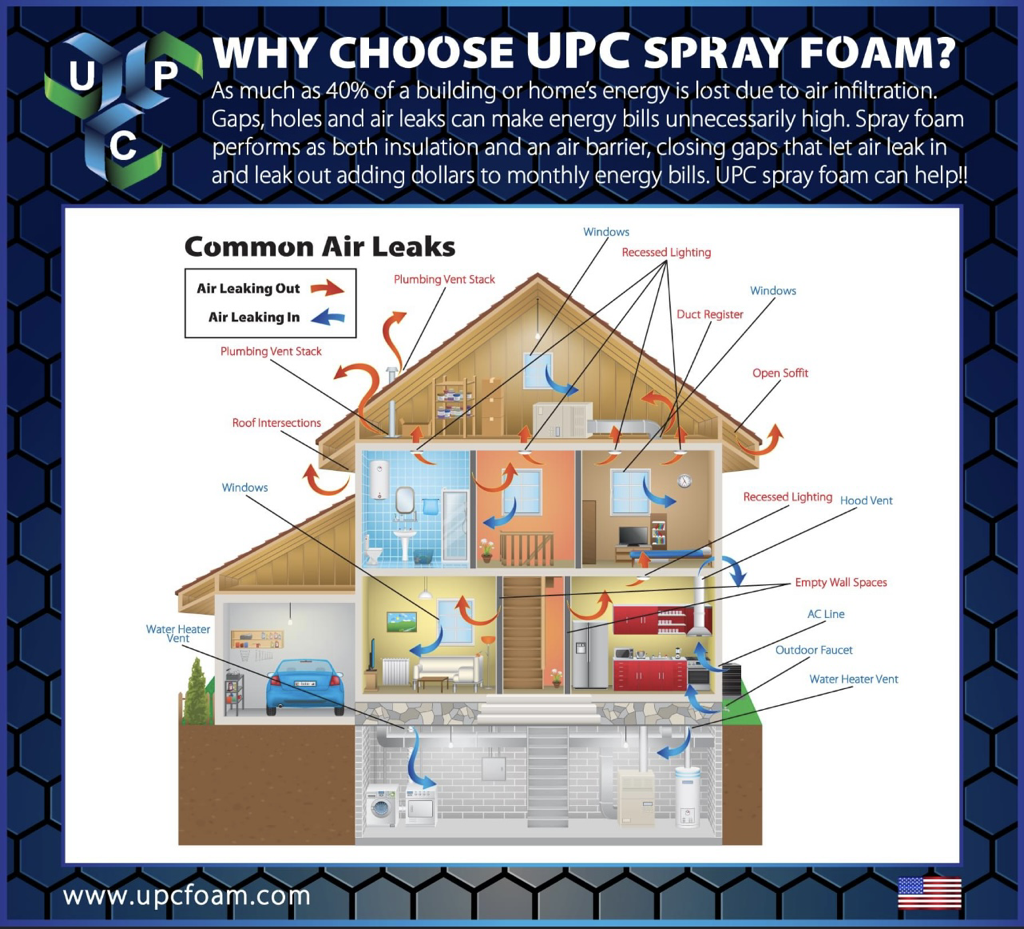

Spray foam has many uses in addition to being the most effective and energy efficient insulation for your project.

Spray Foam Insulation BenefitsStops allergens, humidity, and dust filled air from entering your home or commercial building. |

Common InstallationsTypically installed in attics, walls, crawl spaces, pole barns, commercial flat roofs, basements, garages, and commercial structures. |

|

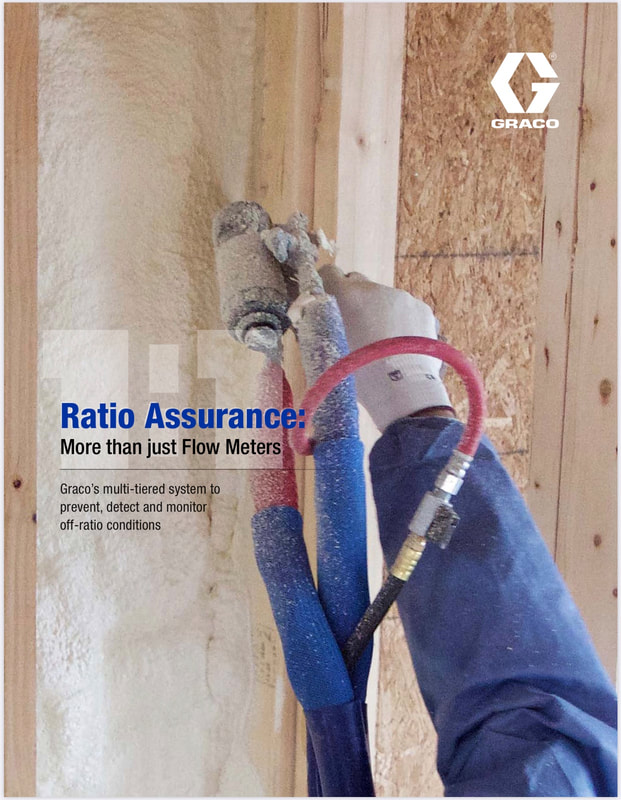

All of Weather Stop's spray foam rigs are equipped with Graco's new flow meters, guaranteeing on ratio, properly processed foam . Spray foam insulation is created at the job sight, using special equipment and highly trained personnel. It is extremely important when creating foam that the two chemicals used are as close to a 50/50 ratio as possible. When the ratio assurance flow meters are used on a spray foam proportioner the machine will automatically shut down well before a trained applicator can tell that anything is wrong, giving us at Weather Stop and our customers the assurance of correctly processed material every time! |

About Weather Stop

Chris Camenisch, owner of Weather Stop, has 24 years of experience in the construction industry. That experience combined with the amazing Weather Stop team and the best equipment available, ensures a quality job and customer satisfaction. Weather Stop is committed to offering the highest quality work with every job we do.

Why Choose Weather Stop?

Weather Stop is a highly-trusted, family owned, local business serving the Kentuckiana area. Our extensive history in the construction industry allows us to understand the materials and environment we are working with, and to provide a custom tailored solution for each project.

Contact us for a free quote.

Contact us for a free quote.

What Should I Expect During and After Installation?

Spray Foam is made of two chemicals that when combined, create foam instantly. A byproduct of this exothermal reaction is strong fumes requiring appropriate ventilation during, and sometimes after, application. This ventilation process takes 12-24 hours before re-entry. Depending on the scope of work, you may not be able to occupy the building during installation. Properly applied spray polyurethane foam will not have lasting odor.